Types of manual sack tip cabinets

Dust collection hoods equipped with gas springs to lock the opening door in position

The differently shaped hoppers are provided with front sack resting table and removable safety grid fixed to the hopper inner walls.

Material discharge into the loading units of mechanical, screw, aeromechanical and pneumatic conveyors takes place by gravity and is fostered by manual or pneumatically operated slide valves. The ventilation channel allows pressurised air to vent, as well as the valve axial sliding.

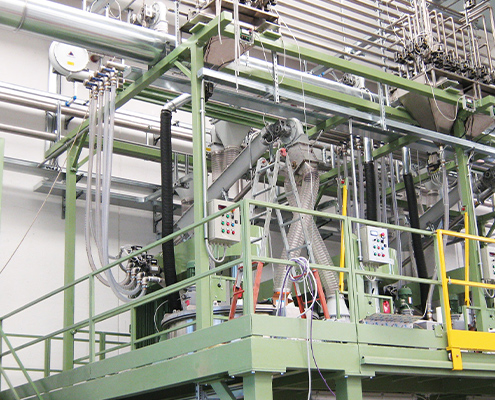

Automatic sack tip cabinets

The material is transferred to the cabinet in sacks moved along a conveyor belt, which includes an isolator with sack cutting blades and a rotary screen separator.

The empty sack fraction (oversieve), cut down into lists, is conveyed to the disposal unit through a screw compactor, allowing further size reduction, while the material fraction (undersieve), sieved and collected in the undelying hopper, is transferred to material collection systems automatically through air flow.

Loading systems

Emptying and extracting systems

Screw conveyor and Lump breaker

STATE AID AND DE MINIMIS

Information obligations for public grants.

State aid and de minimis aid received by our company are contained in the National State Aid Register referred to in art. 52 of Law 234/2012 to which reference is made and which can be consulted at the following link: Learn more>>