Types of hoppers

The hopper geometrical shape is significantly affected by the material flow profile, which as a result of condensation, crystallization, fermentation reactions and moisture presence determines the material accumulation along the bin’s walls or edges, hindering the reliable discharge of the material. The hopper inclination angle as well as its discharge section are decisive for a uniform emptying.

In the hoppers:

- the filling (loading phase) takes place from the top, by gravity, by means of silos, FIBC emptying stations, mechanical, aeromechanical, screw and pneumatic conveyors;

- the emptying (discharge phase) occurs from the bottom, by gravity, through screw conveyors, rotary valves, butterfly valves and dedicated extracting devices.

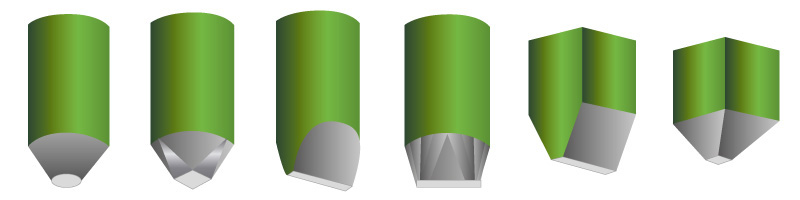

Hoppers for mass flow

Steep and smooth hoppers, with walls and angles that have an even finish, a cylindrical, rectangular or square shape and bottom:

- truncated-conical

- with a square opening

- chisel-shaped

- pyramidal wedge-shaped

- truncated-pyramidal

suitable for fine powders, for not very fluid and easily degradable materials, designed to reduce storage time leading to product decomposition, segregation, oxidation. Emptying takes place in a first in – first out flow sequence.

Hoppers for funnel flow

Hoppers with low sides and reduced wall inclination, with a cylindrical, rectangular or square shape and bottom

- pyramidal with a square opening

- truncated-conical

- flat with slot opening

- flat with circular opening

used only for coarse powders, free-flowing and nondegradable materials, so that the stationary material does not lead to abnormal segregation or efflux. Emptying takes place in a first in – last out flow sequence.

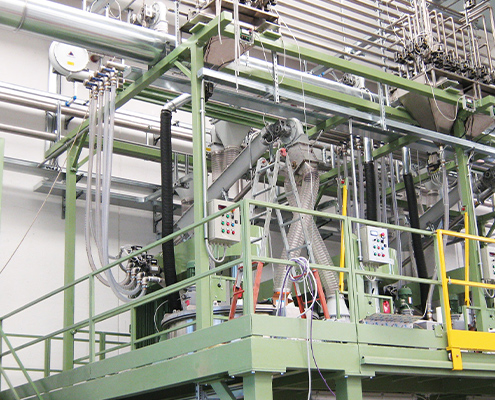

Loading systems

Emptying and extracting systems

- Vibrating bottom

- Aerated bottom

- Plated bottom

- Butterfly valve

- Rotary valve

- Screw conveyor

Level control method

- Ultrasonic level transmitters

- Capacitive level switches

- Conductive level switches

- Rotary level switches

- Membrane level switches

Second method

- Weighing hoppers

Mixing

Homogenizing hoppers

Mixers

STATE AID AND DE MINIMIS

Information obligations for public grants.

State aid and de minimis aid received by our company are contained in the National State Aid Register referred to in art. 52 of Law 234/2012 to which reference is made and which can be consulted at the following link: Learn more>>